IPE Design

IPE’s design facility was created to provide our clients with the option to develop innovative custom solutions. Our services include 2D & 3D modelling, animations, detailed drawings, assembly drawings etc. We can also provide prototyping to ensure the design is sound and offer pricing for both local or offshore manufacturing (IPE quality control + delivery).

IPE Integration

Although IPE can provide a full custom solution it can often benefit the client to modify existing ‘off the shelf’ equipment to save on cost and time. Where possible IPE offers to integrate with external equipment / structures / control systems or alike to help provide a better solution for our clients.

IPE Turn Key

IPE turn key encompasses the entirety of a project. We can offer a complete solution whether it is equipment focussed, unique processing, control systems, manufacturing lines or a completed factory build.

3D modelling

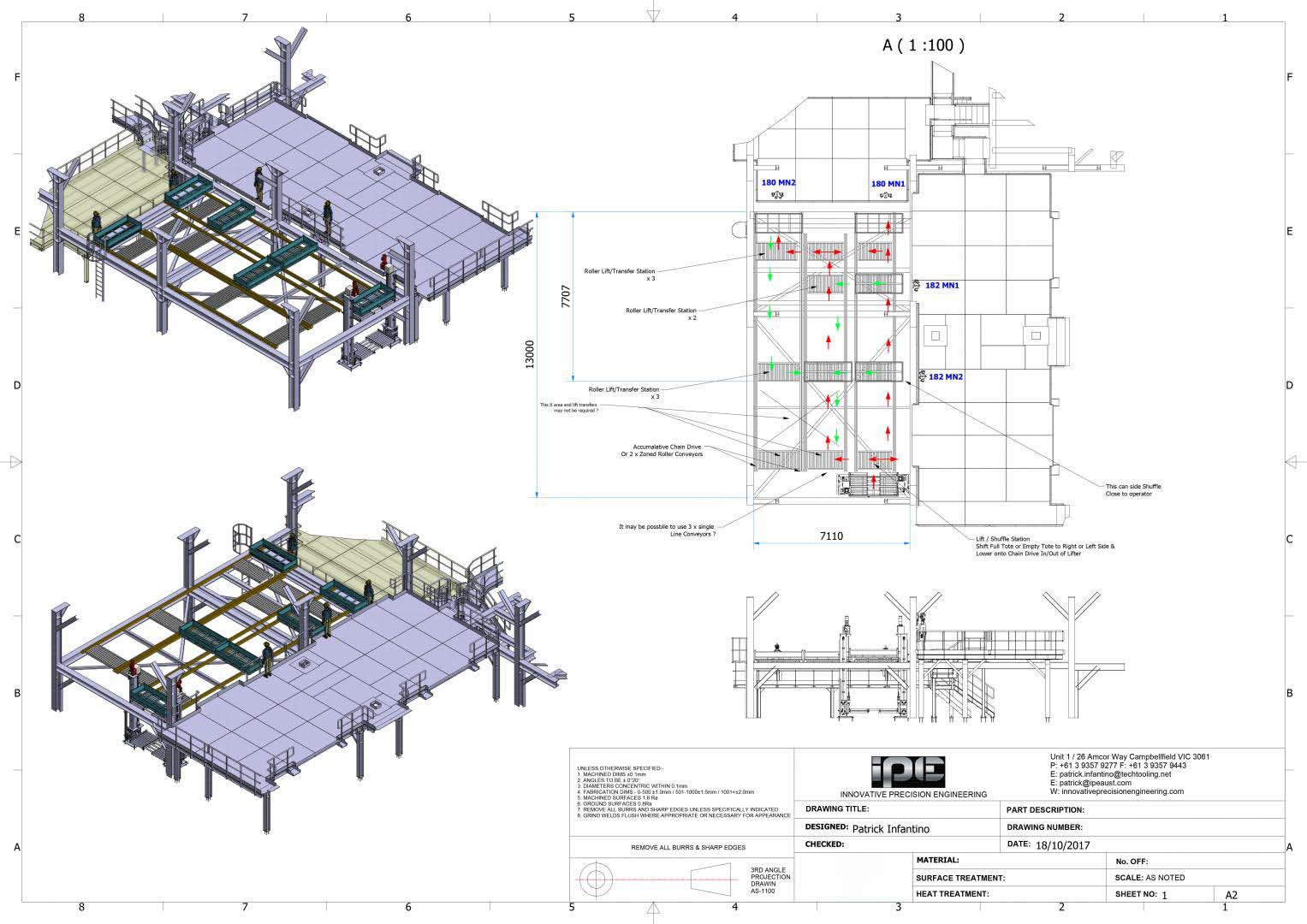

3D modelling is a core tool that IPE utilises to provide accurate designing for our clients. It provides a clear method for communication and visualisation of the design at hand. The design team can provide full 3D drawings for process / equipment confirmation long before the cost to manufacture has been committed.

The drawings provided above include two special purpose part fitment machines and a factory structure. The factory structure confirms that the equipment being developed will fit in location without conflict.

Factory design / Line Builds

IPE has over 10 years experience in the latest production line developments and over 20 years experience in machine design.

Our latest manufacturing line is over 100 metres in length and integrates special purpose equipment with cost effective fabrication.

Watch the video to view our concept design for a twin back to back manufacturing line that integrates robotic transfers and lifts.

- Reliable

- Cost effective

- Maintenance friendly

- Efficient

- Flexible

- Innovative

- Space conscious

- Lean

- Process flow

- Material flow

Project Management

Experience

Project management is a core tool that IPE utilises to ensure good service and on time delivery of product. We have managed projects that coordinate in excess of 12 companies with services ranging from plumbing to structural engineering.

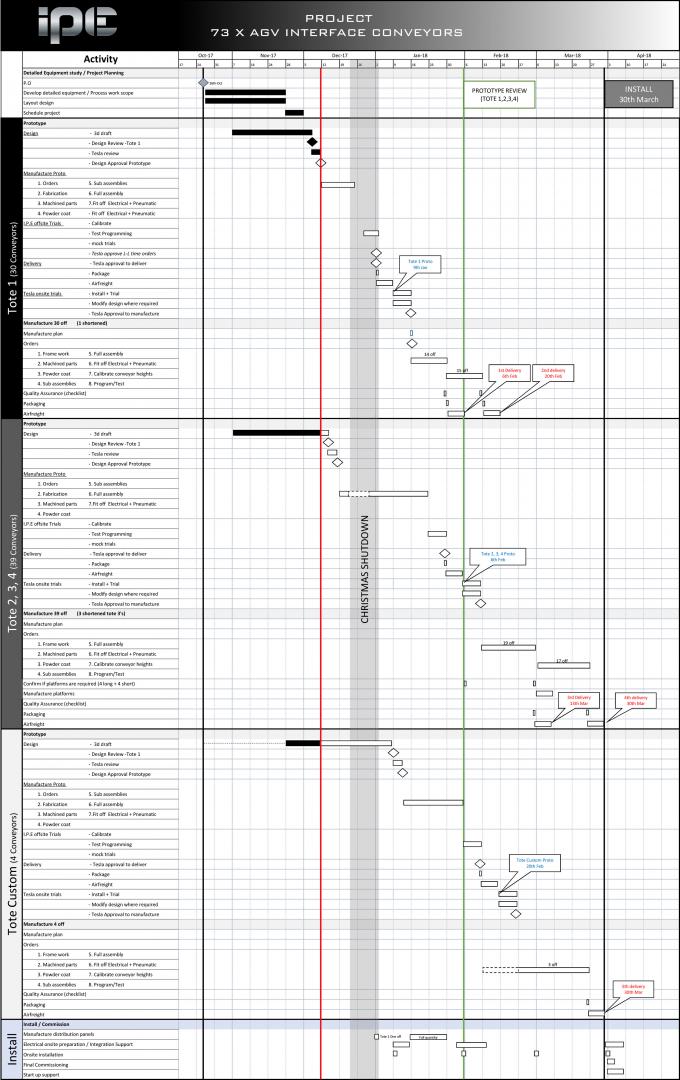

Scheduling

IPE provides a schedule with every project / venture to provide a clear work breakdown structure and the associated timing of each activity. This schedule is updated and provided periodically to our clients.

Communication

Weekly meetings are organised to ensure the direction of the project is to client satisfaction or adjusted to suit. These meetings can be held at IPE or we can also work with internet communication platforms such as ‘Zoom conferencing”.

Commitment

To Deadlines Developed on the backbone of the automotive industry, IPE has been exposed to and achieved ‘all or nothing’ deadlines. We share with our clients in the commitment to aggressive but achievable time frames.

Support

IPE support not only includes the duration of the project and the installation, but also post installation to ensure that the equipment continues to operates as originally intended.

Service

The IPE team is dedicated to providing good service to our clients throughout the duration of the project / venture and after. We enjoy a fun but efficient relationship with our clients and like to celebrate the goals and success we achieve as a team.

3D printing

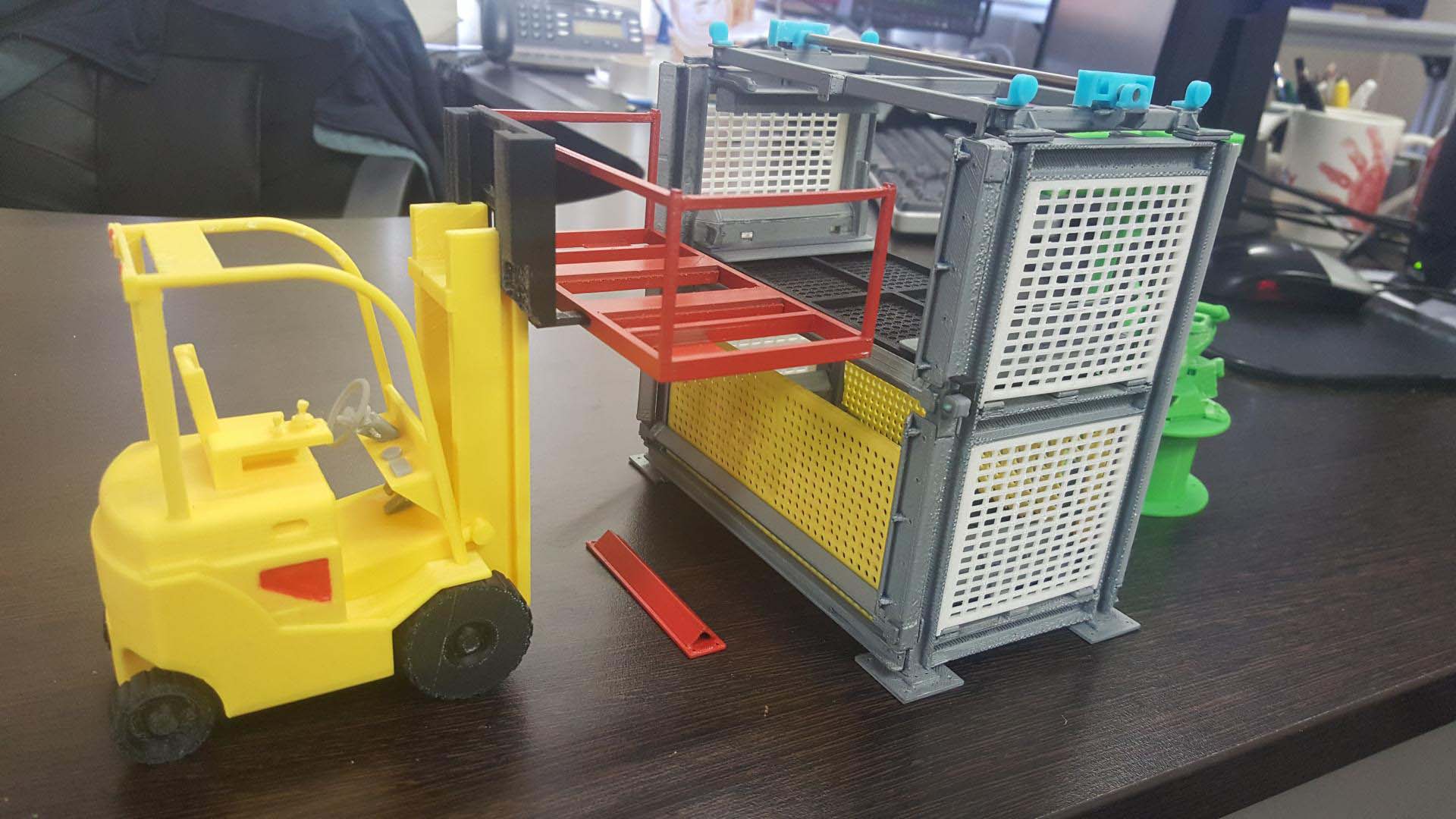

The creative world constantly searches for better methods to improve the way we build. Additive manufacturing is one of the major growth area’s that IPE supports and utilises through the use of 3D printing.

Pictured left is a 1:1 scale (3D printed) prototype fitment jig. This 3D print allowed us to confirm the jigs ergonomics before we committed the cost and time required for machined aluminium parts. Essentially promoting the engineering phrase “don’t tell me, show me”.

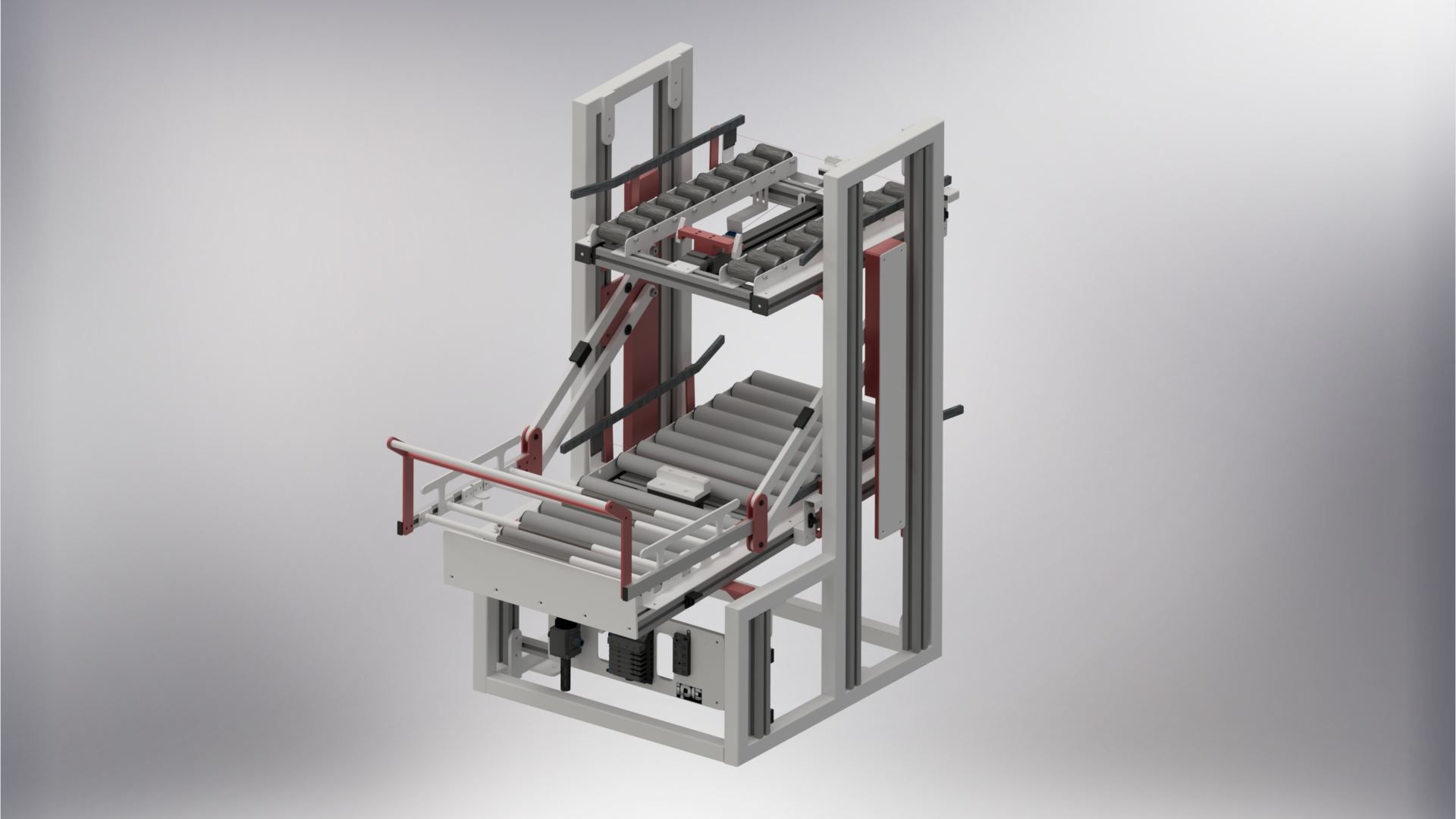

Pictured above is a 1:20th scale 3D print of an ‘automated rack tower’ that IPE created to support a communication gap found when providing 3D drawings to our clients production and material handling members.

Simulations

Our ability to provide equipment silulations have been an effective method to communicate process steps to our clients. The simulation can help to identify process concerns within the design stage of the project.

For example, the simulation below highlights the basic steps that our mechanically operated (3 tonne) conveyor takes to index forward stacked gearbox modules.

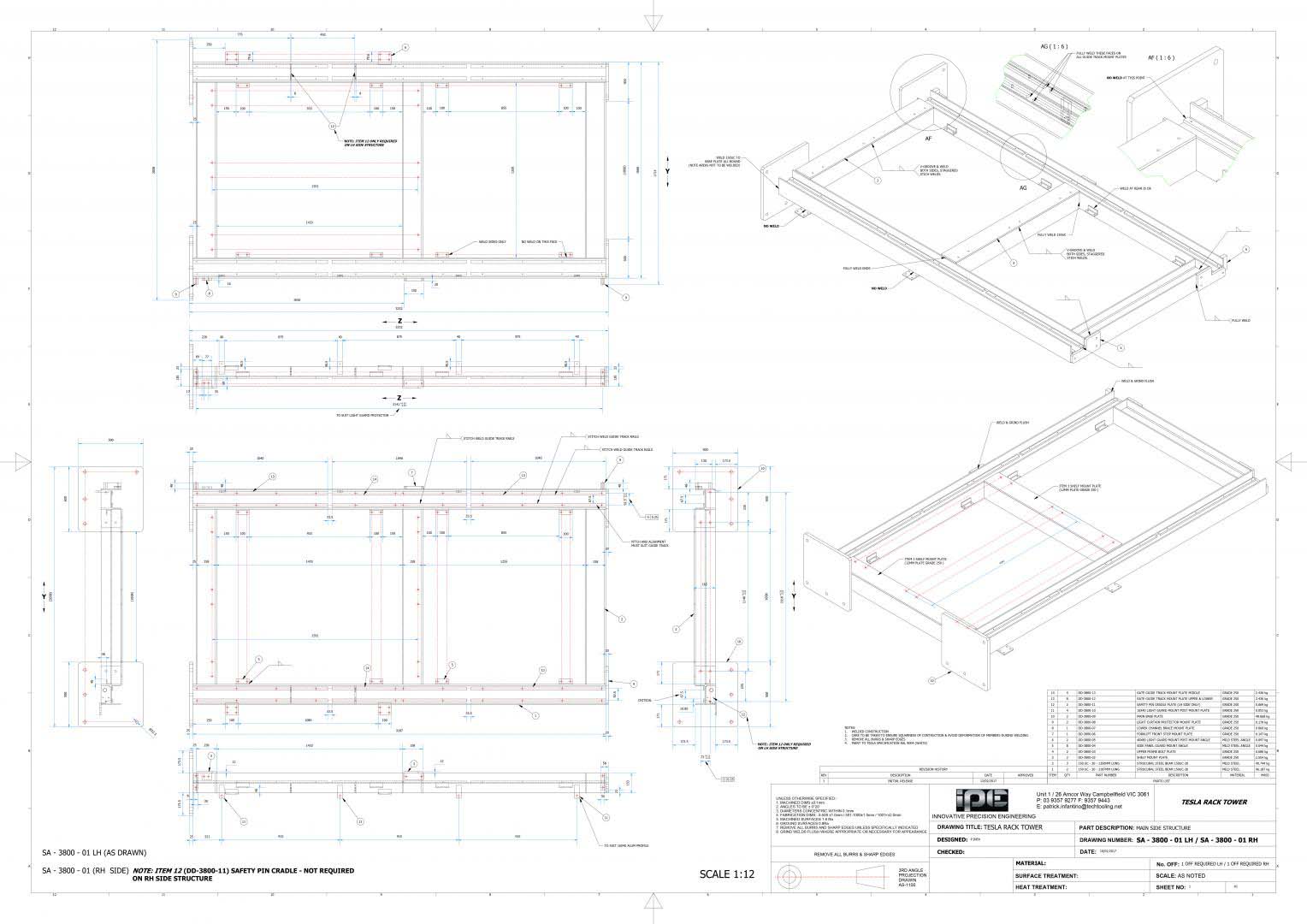

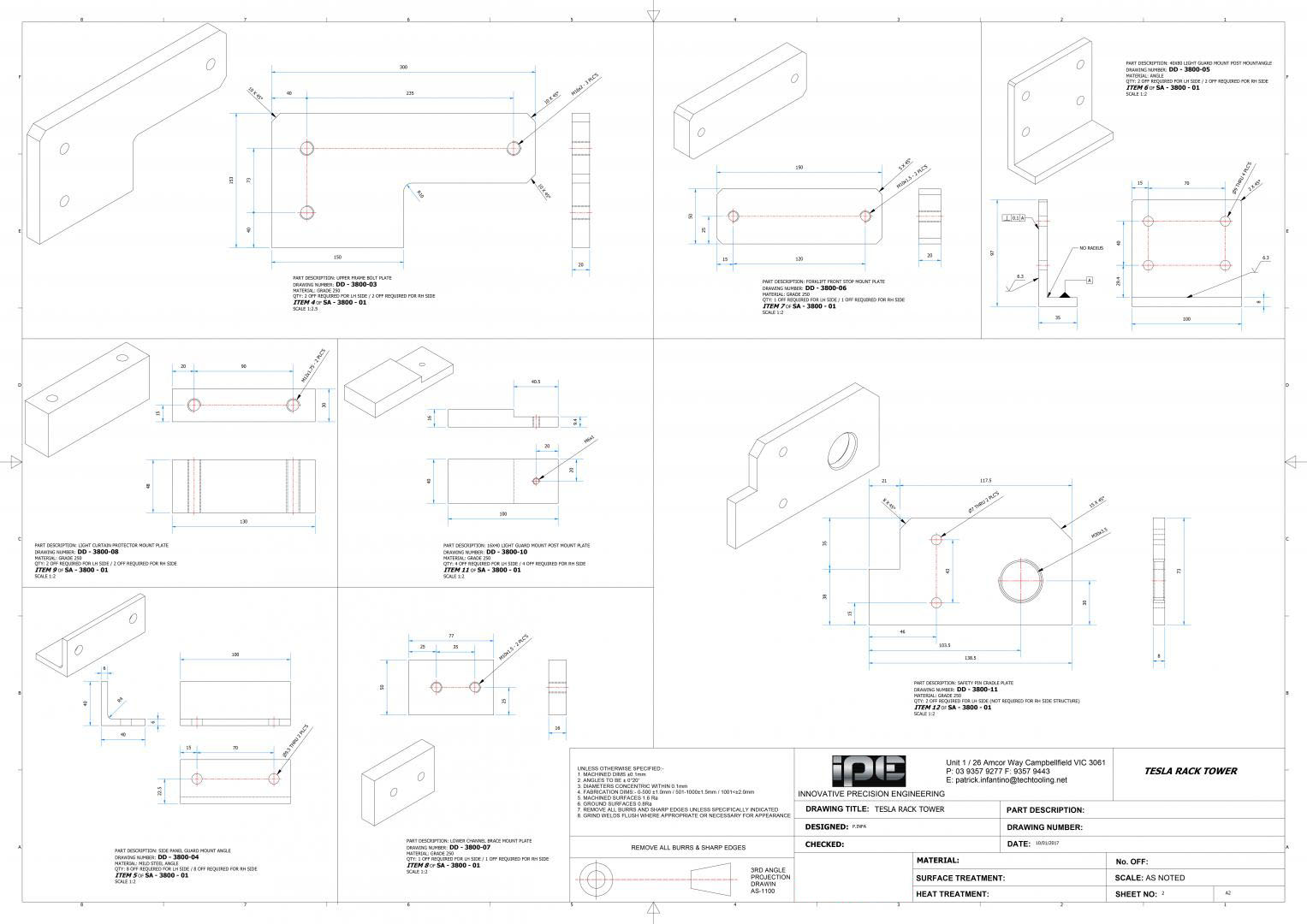

Detailed Drawings

IPE can provide detailed drawings as a part of its design scope. In general practise, we detail our drawings in a manner that favours our form of manufacturing and team. However we can provide drawings to suit our clients needs and multiple forms of manufacturing.

Main side structure - sub assembly

Main side structure - connecting bracketry

Assembly drawings

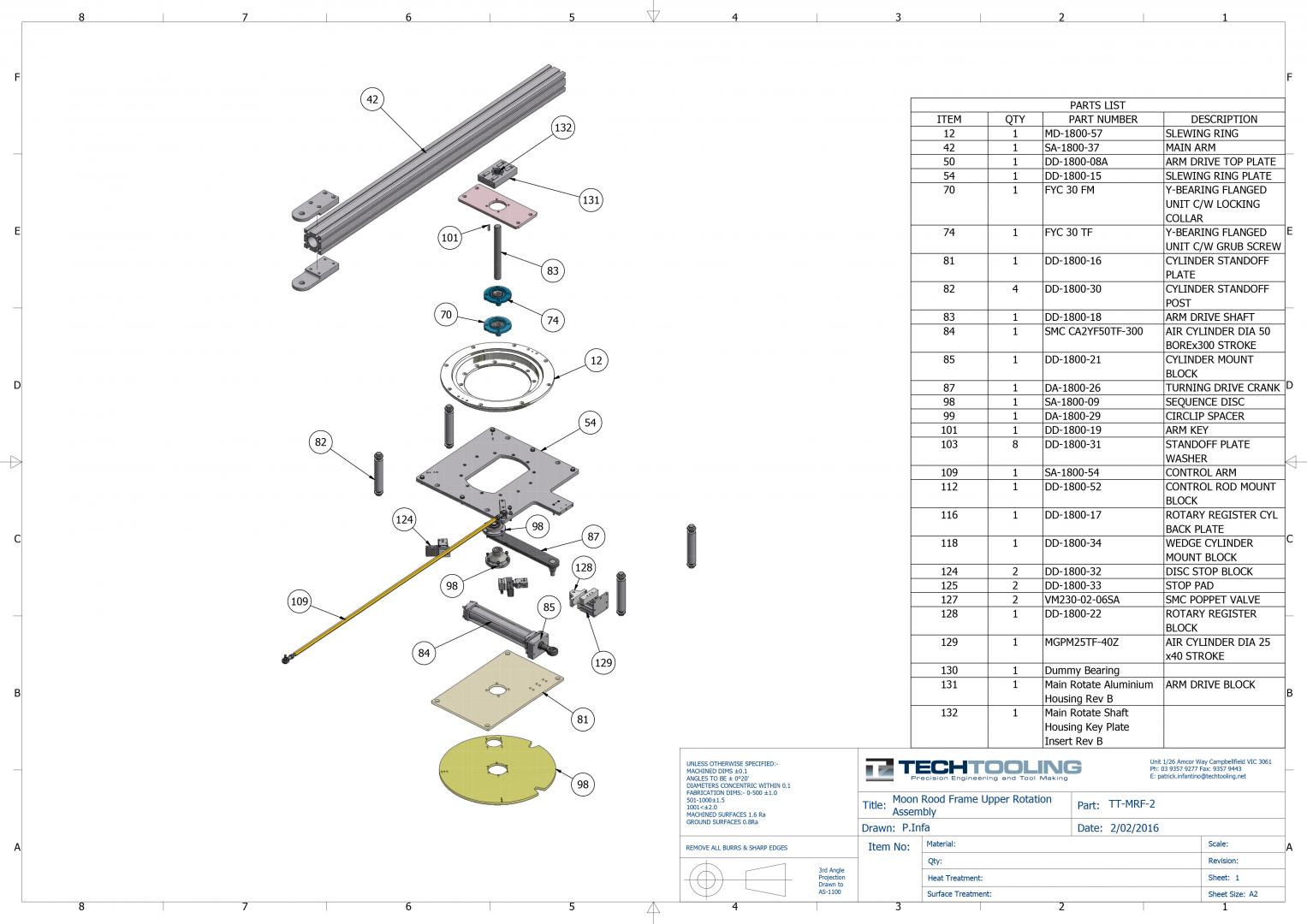

Moon Roof Arm Upper Rotation Assembly

Exploded view to highlight internal componentry for maintenance support and ease of spare parts ordering.

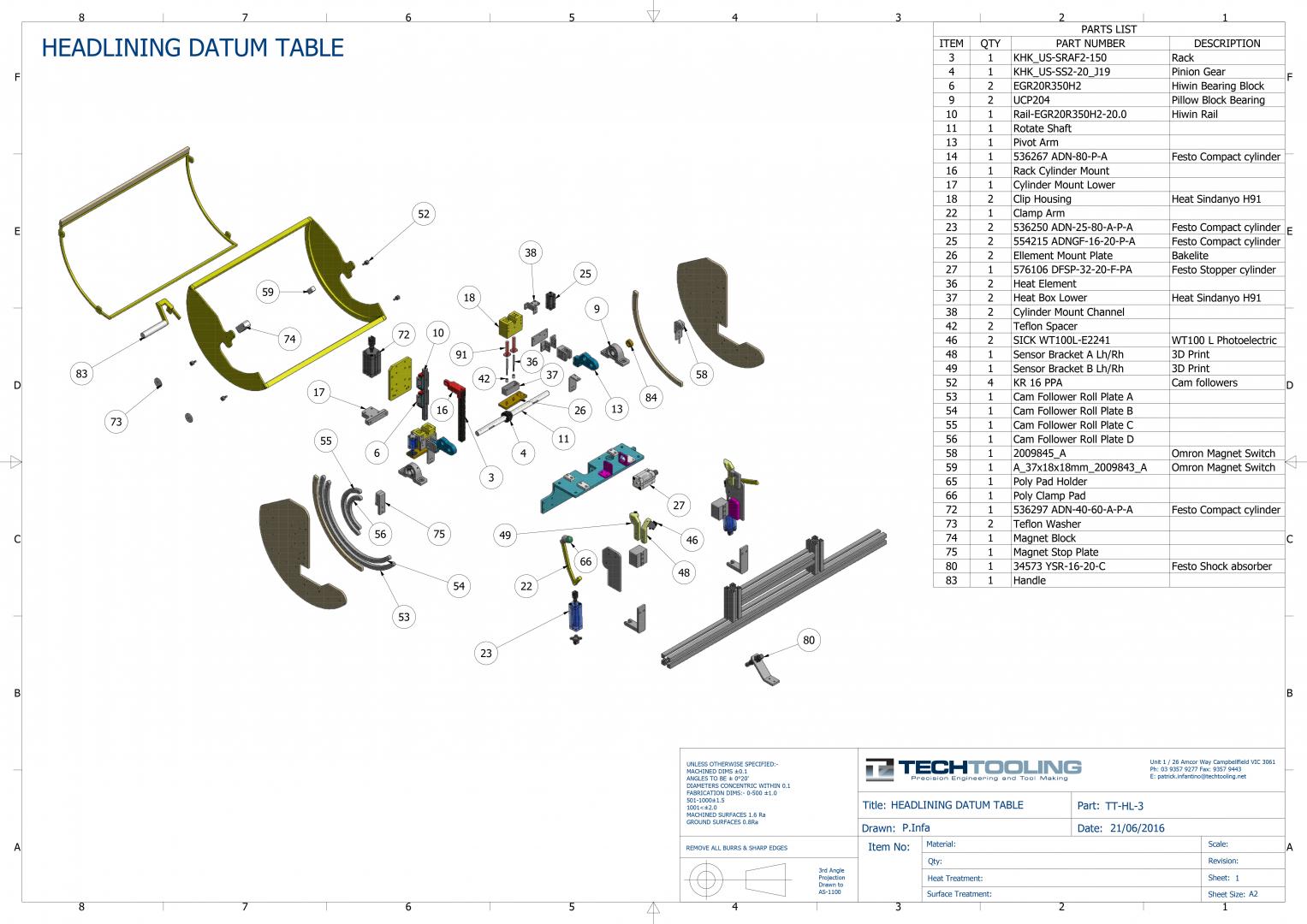

Headlining Datum Clip Locate Assembly

Exploded view to highlight internal componentry for maintenance support and ease of spare parts ordering.

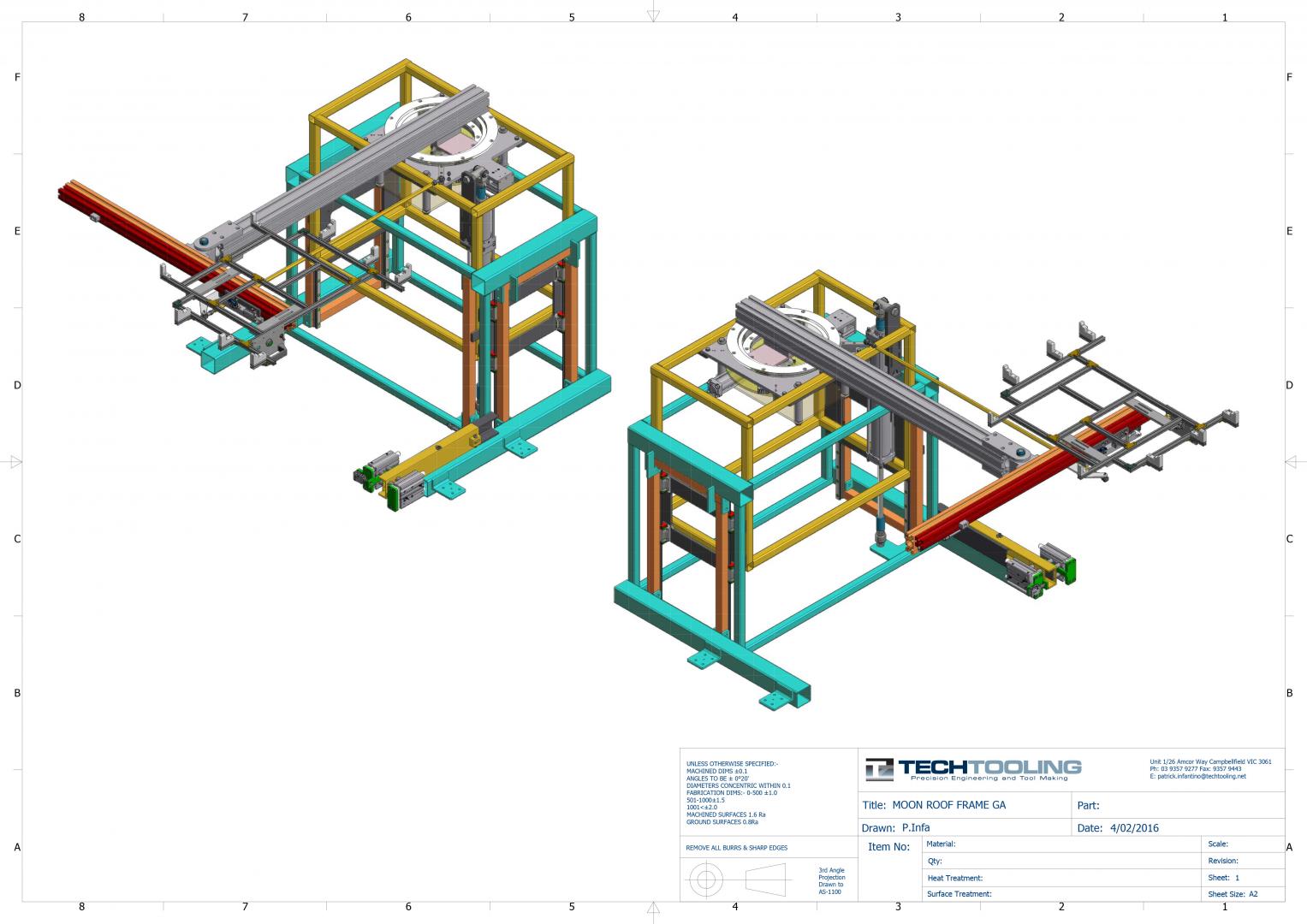

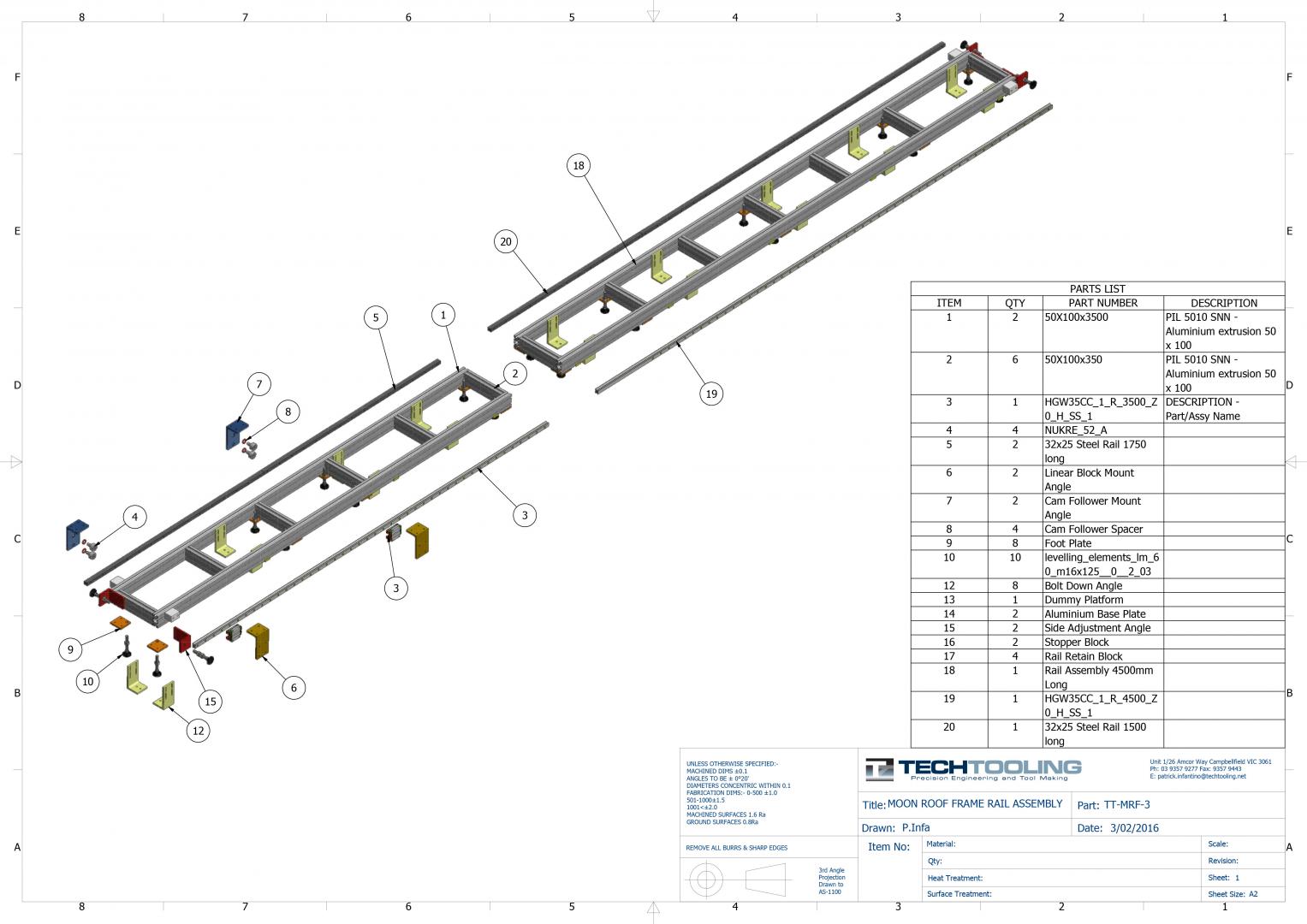

Moon Roof Frame Rail Assembly

Exploded view to highlight internal componentry for maintenance support and ease of spare parts ordering.

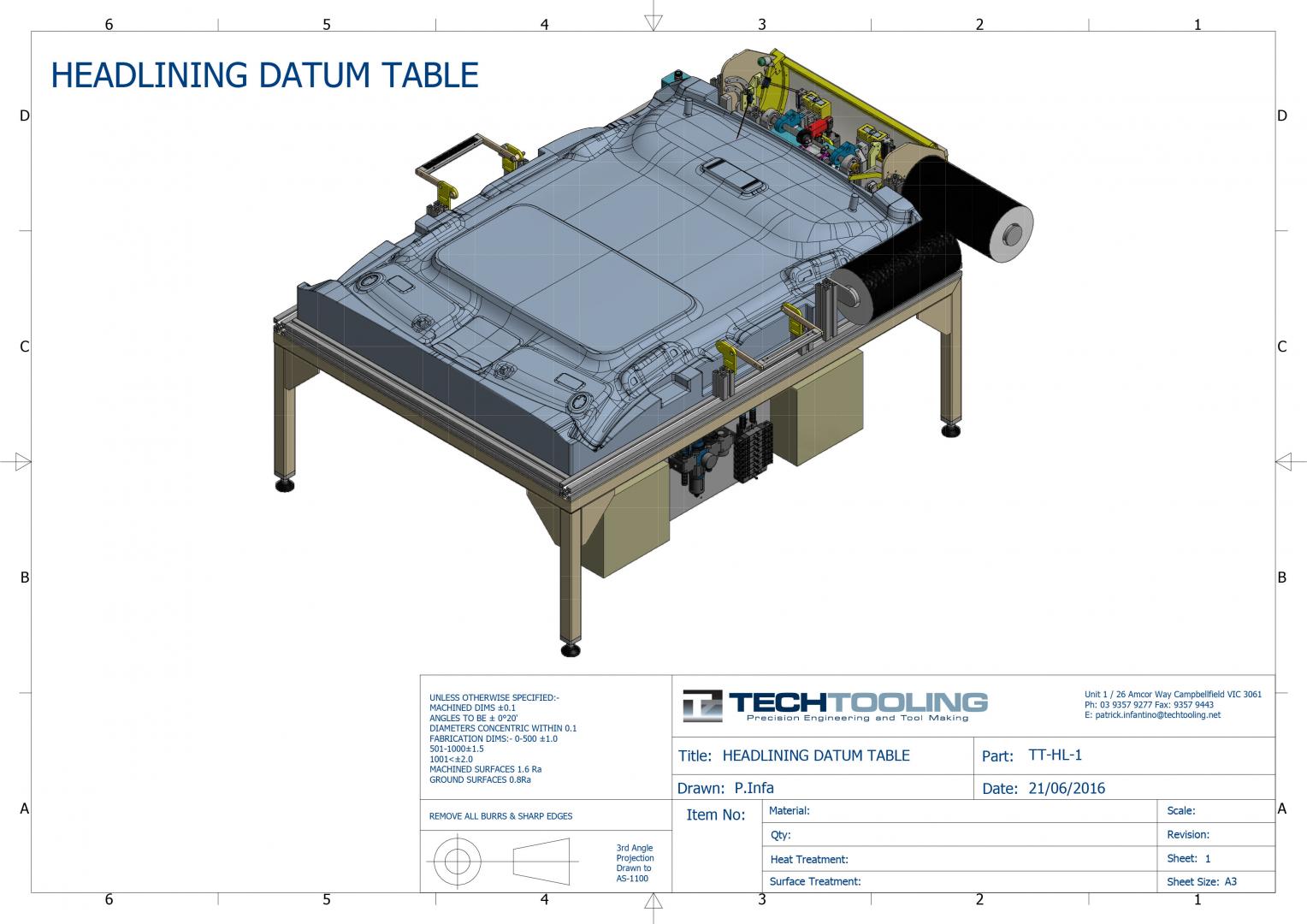

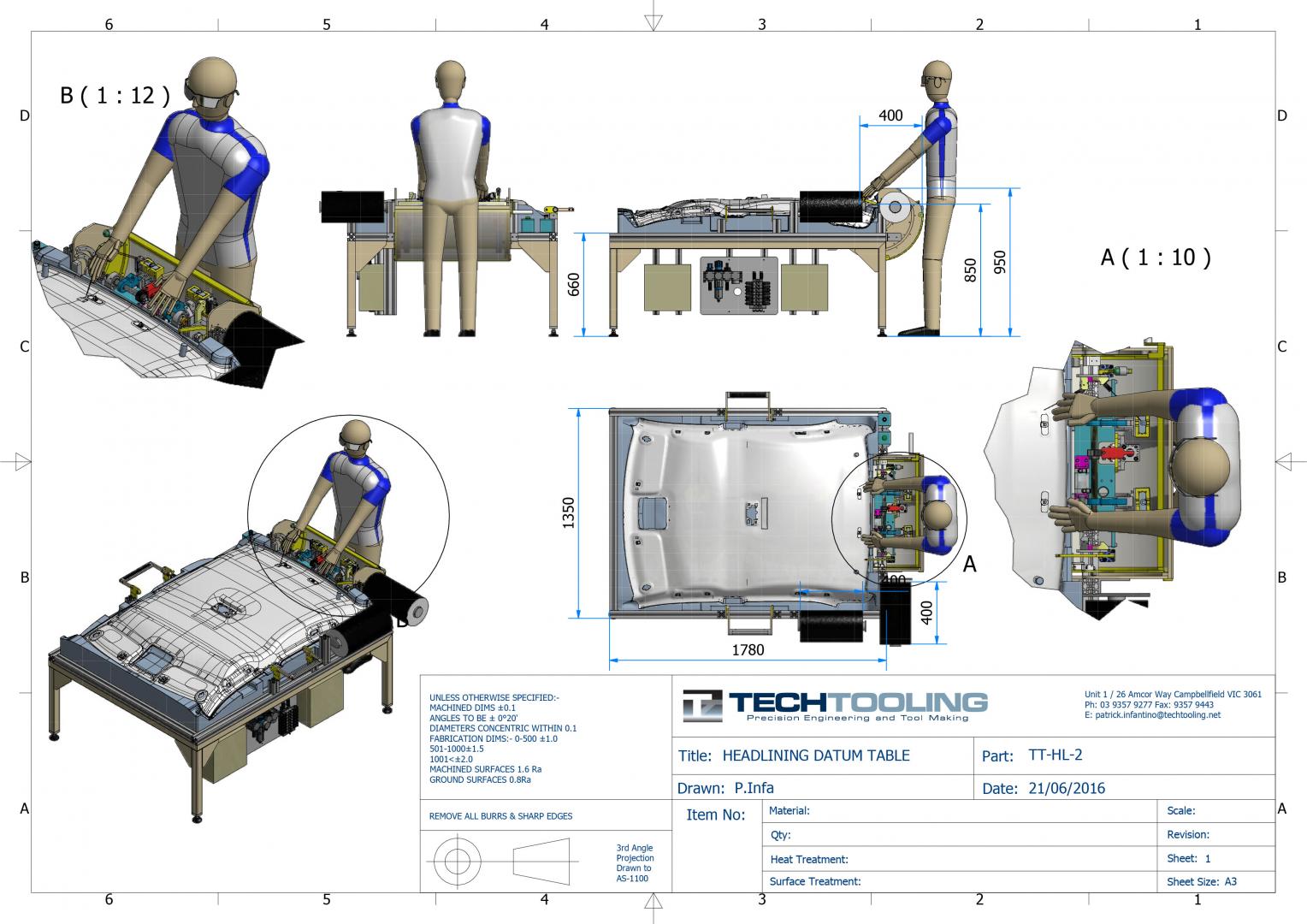

Headlining Datum Table Assembly

Design stage ergonomic assessment. Confirmation of process height and team member reach